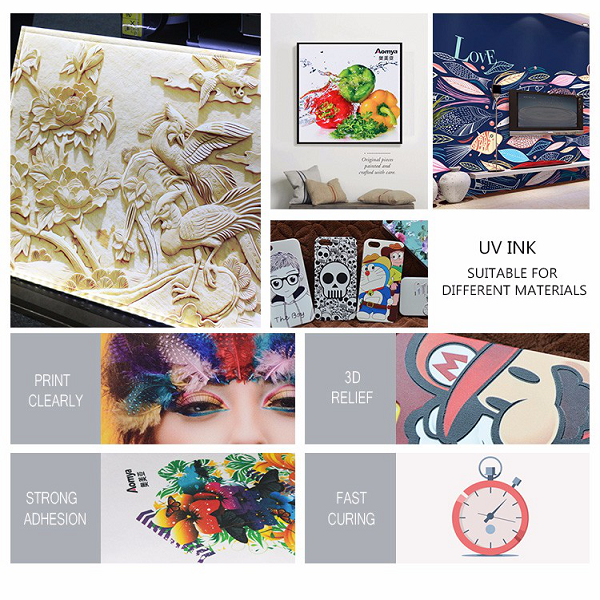

The development of UV printing technology has opened up new opportunities for printing companies to print on different types of printing materials. In the past, the image on the glass is mainly through painting, etching and screen printing to achieve; now, can be achieved through UV inkjet flatbed printer technology.

The biggest trend of glass printing is to be able to get high-end, high-quality color appearance. In addition, although the use of glass printing is one of the largest retail goods, its application in the construction, engineering, interior design is also more and more widely.

1, In the new substrate materials

Through the glass printing technology, painters can have better performance.

The painters can in the dining table, coffee table, glass shower door, charging table, glass plate and other things on display and sale of painting, the artistic expression and combining with the development of UV printing, they found a new canvas”.

2, Printing process

Painters and interior designers found that the reverse printing of glass is a very effective way, without the use of tackifier. Printed on the reverse side, or “second surface printing”, allows the final product to be protected by the glass itself.

3, Do not need coating

Non coated glass can also be successfully printed on glass UV.

With low light curing on glass printing, and printing to make prints channel curing, “double seal glass printing, or glass etching is used to replace add thickening agent or liquid coating layer, are protective glass.

4, Make the canvas with glass

The photographer, artist, printers, print maker and author BonnyLhotka has developed the SuperSauce solution, which contains about 91% isopropyl alcohol, used to transfer the image to the glass pigment inkjet printing.

Post time: Jun-29-2022